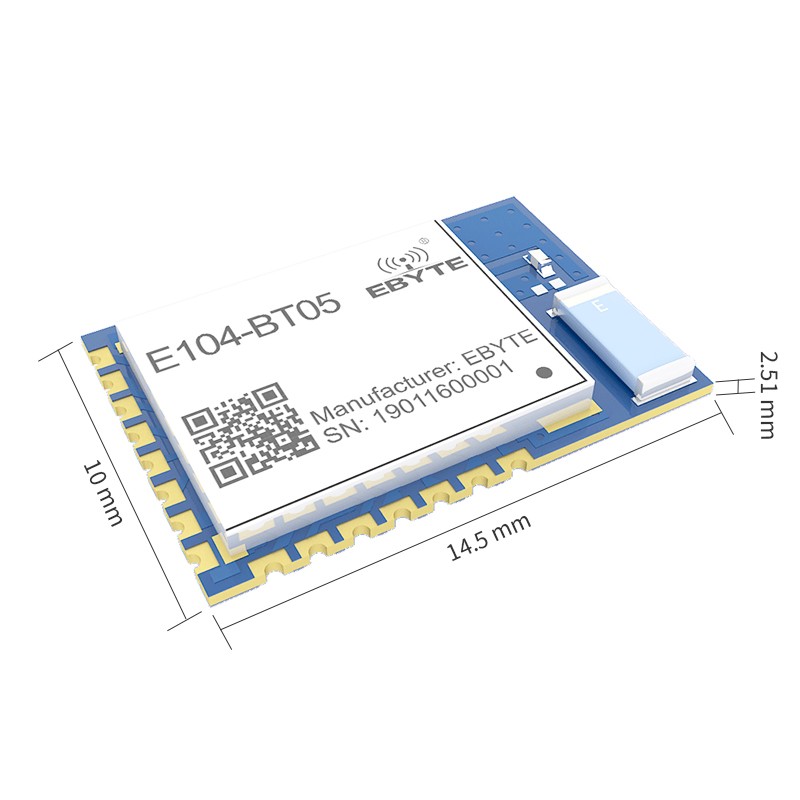

E104-BT05 is a serial-to-BLE Bluetooth slave module based on Bluetooth protocol 4.2, working in the 2.4GHz band. This module supports low-power broadcast, data transparent transmission, control configuration, IO port level reading, IO port level setting, and variable frequency PWM output. The module can be widely used in smart wear, home automation, home security, personal health care, smart home appliances, accessories and remote control, automotive, lighting, industrial Internet, intelligent data acquisition, intelligent control and other fields. Maximum support for data transmission with a baud rate of 256000 bps.

Application of battery data collection in mine equipment

The E104-BT05 module is small in size, light in weight and low in power consumption. It is suitable for embedding into various small collection devices. Here, the equipment battery in the mine is detected as an example.

Advantages of using E104-BT05

1. The module supports low-power broadcast of user-defined data format. Putting the detected device battery information into the broadcast package enables any host device to scan the data information without additional development communication protocol.

2. The module supports low power mode. Users can change the broadcast gap and turn on the low power mode according to requirements. The minimum power consumption current can reach 8uA, and a button battery can meet the long-term monitoring of mine equipment.

3. The module supports the air configuration. After embedding the E104-BT05 module into the device, the module parameters can be modified at any time according to the air configuration command to adapt the user requirements.

4.The module also has an additional IO port level acquisition function, which can reduce the user's MCU development, directly use the E104-BT05 module air configuration command to read the relevant IO port level.

Program structure

1. The mine contains the data acquisition terminal of E104-BT05.

2. A data receiving terminal supporting host functions, such as a mobile phone APP, a small program, and a PC-side data receiving software.

The workflow is as follows: the mine equipment collects the battery information and packs it according to a certain format, and the packaged data information is transmitted as a parameter to the broadcast package of E104-BT05 (using the broadcast packet data of E104-BT05), and the terminal monitoring device scans the broadcast. Data acquisition device information.

Intelligent control application

The E104-BT05 comes with two IO outputs and four PWM outputs with variable cycle frequency. Therefore, it has great advantages in the field of intelligent control and can directly control related devices. Here, the control of the intelligent robot arm is taken as an example.

Advantages of using E104-BT05

1.Small size and light weight will not impose an additional burden on the robot arm.

2. with 4 PWM output, 2 IO output, users can directly set the cycle and frequency, reducing the cost of additional microcontroller.

3. The module supports air configuration and can be equipped with mechanical arm parameters anytime and anywhere.

Program Structure

1. Intelligent robot arm control terminal.

2. Intelligent robot arm execution terminal including E104-BT05.

Precautions:

1. When using, you need to configure related parameters such as device name.

2. The serial port assistant can be used for the control on the PC side, or the related interface control software can be developed by itself.

3. The control of the arm is generally based on the PWM control. It is assumed that the PWM1 output period is 10ms and the duty cycle is 10% PWM wave. The calculation method of PWM period is as follows: within the module, we set the precision to T=0.01ms, that is, the minimum period that can be set is 0.01ms. The parameter can be input when setting. If the setting period is 10ms, then t=T*para. Bring T=0.01ms, t=10ms, and calculate para=1000.

Please contact us to know more details.We can provide more application.